42 best way to label warehouse racking

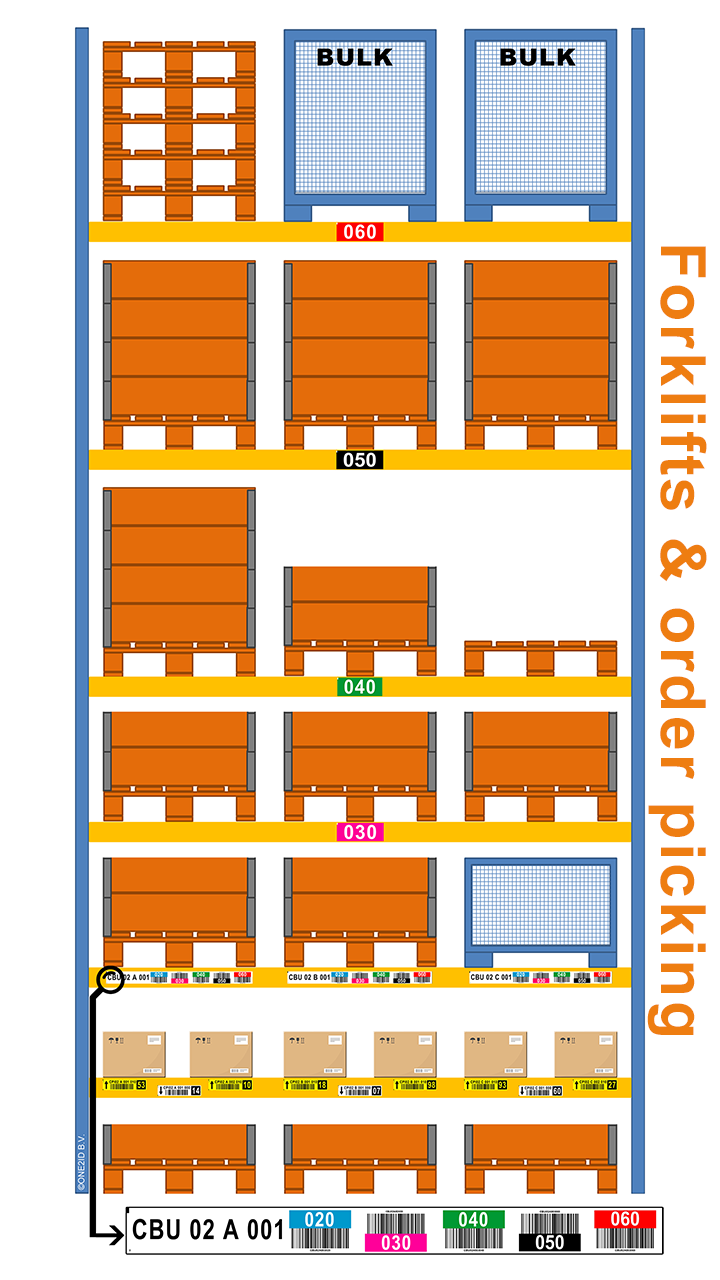

New Warehouse Design? Tips on How to Label Warehouse Racking - LIDD Ways you can keep flexible level numbering include: Begin the pick levels at the start of the alphabet (A, B, C starting from the ground up) and the reserve levels from the end of the alphabet (Z, Y, X working from the ceiling down). Identify the pick levels using numbers and the reserve levels using letters Warehouse Racks Labeling Guide & Idea - SPS Ideal Solutions Label from Bottom to Up: It is always a good practice to stick the warehouse racks label from bottom to up. The bottom row must carry the serial no 01, and when moving upwards it must be 02, 03, and 04 and so on. This practice of numbering is beneficial when there are any future upgrades by adding rows to increase the height of the racks.

5 Keys to Warehouse Rack Labeling | Express 3) Grid or serpentine layout - When envisioning a warehouse and making plans to use warehouse labels most effectively with racks, it is essential to decide how the layout will be done. When a warehouse has to address the issue of picking and packing orders strategically, the layout of the racks is best done in the curving style known as serpentine.

Best way to label warehouse racking

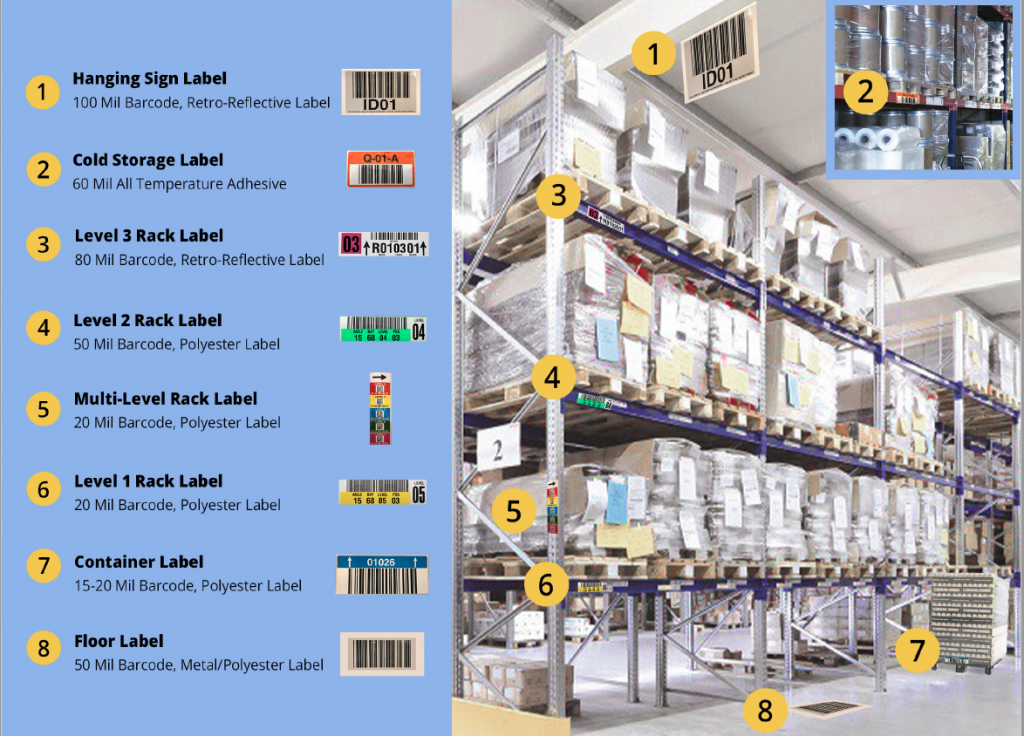

How To Label Warehouse Racks | inotec In instances of gravity-fed racking, inotec recommends placing a label at both the front and the back of the racking to serve the restocking and retrieving of products. Shelf Labels Shelf labels are a simple yet popular choice for smaller warehouses. They are commonly used for smaller volumes of racking with a basic shelf layout scheme. How to Barcode your Warehouse - DataNinja We hope the following 8 tips help you implement a user-friendly warehouse barcoding system. 1. Make the Coding logical I mean two separate things here. (1)Make the human readable bin locations easy for humans to remember, and (2) make it easy to translate a bin location ID, to its physical location in the warehouse. Label Magic™ - Warehouse Rack Refacing & Label Removal Dasko offers Label Magic™ as a simple solution for rack and beam cleaning, and label removal. Visit our site to learn more about Label Magic™! The Warehouse Label Specialists - (866) 286-6500. Products. Warehouse Labels; ... DASKO Label 1 New Industrial Way Suite 2 Warren, RI 02885.

Best way to label warehouse racking. What Are The Ways to Label Bin and Rack Locations? Before you could even start with implementing a labeling system for your warehouse to drive efficiency, it woud be best to map and segment your warehouse and assign specific location names for each of these segments. These location names and references will be the basis for the location code that will be used by your bin and rack label system. How to Label a Warehouse - Express Corp Shelves: The common and preferred method of warehouse shelf labeling is by section. Each shelf within a unit should count up from one and continue numerically until you reach the end of a shelf aisles. Depending on the warehouse, you could decide to put your shelf value in the last position of your location code. How to Label a Warehouse Rack - Camcode But, even if you are a small operation that is using bare-bones racking solutions, like two-shelf pallets, you will still want to label your racks from the ground up, by giving the lowest row the name of '01'. The second row will be labeled as '02' - and so on, and so on. Common Types of Warehouse Rack Labels - Informs Inc. Warehouse Rack Beam Labels These are the labels you will most commonly find on warehouse racks. They mark each bay location, and typically use 2D barcodes for scanning. They may also have letters and numbers for workers to identify contents without scanning.

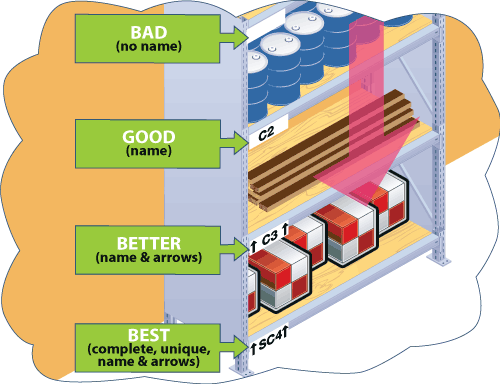

Warehouse Signage and Rack Labeling - EMP Tech Group An alternative is to put one placard down low with several smaller shelf location labels. The right decision for this step depends on the type of lifts you are using and the type of bar code scanners in your mobile computers. For the most part, labeling the actual location and avoiding multiple label placards is the best way to go. 3 - Label Types How to Use Warehouse Labels Effectively - Cyzerg 1. Make the System Sequential. Warehouse labels should be used in a sequential system for employees to locate any item in the facility quickly. Numbering the aisles, racks, shelves, and bins is a lot more effective than using any other indicator, such as colors or symbols. Also, using a numerical system gives you the freedom to add more aisles ... Best Practices for Warehouse Labeling - Supply Chain & Logistics Basics Some of the top factors to consider when labeling your warehouse include barcode scheme, label materials, label placement and supporting technologies. Here we will look into each topic more in depth. First, identifying the barcode scheme that works for all parties involved is standard - both the GS1 and UPC schemas are used frequently. 4 Proven Options for Relabeling Warehouse Racks - ID Label Inc. Removable Warehouse Labels If your beams are in good shape, consider using a preprinted, removable barcode label. Like the other options above, a removable label makes it easy to relabel rack locations. They are simple to install and offer location flexibility, without any need for scraping or cleaning to remove them.

Creating a warehouse location numbering scheme? Read this first! Level or shelf - should be assigned and address from 1 to 9 ascending from the floor. If you have more than 9 levels you should start with 01. Position - assign numbers to each position ascending from 1 to 9, from left to right as you face the rack. Here's an example of a location label where the format is Aisle - Rack - Level - Position. Warehouse Rack and Beam Labels - Labelmatch Labelmatch Warehouse gives you the backing of one of the top experts in the industry. We can design, test, produce and install your warehouse signs and labels. Use our best-practice understanding of warehouse operations, barcode scanning and label production. Our vast experience speeds the process and eliminates potential mistakes. Warehouse Rack Labeling Ideas: Keep An Organized Warehouse Serpentine method - The serpentine method is the most efficient way to label racks. This method involves labeling racks from left to the right, then at the end of the row, continuing to count up only this time from right back to the left, and so on and so forth. This method gets its name from zig-zagging back and forth on a rack. Best Practices to Surviving Warehouse Re-labeling In fact, Lennox uses 5,000 customized magnetic rack labels in its warehouse in Georgia. ... In bulk storage and dock areas, hanging signs are often the best way to go. Camcode's retro-reflective signs hang from a chain or wire and scanned from distances up to 50 feet. The Lennox DC mentioned earlier uses 1,300 of ID Label's retro-reflective ...

A Guide to Labelling Warehouse Racks - Racking & Shelving Label all racks from the bottom up and mount the labels strategically so that they don't hinder any normal activity. Labels should also be fixed in a place where they can't be easily ripped or damaged but are clearly visible to guide staff members. Pick top-quality labels

How To Make Good Labels For Inventory Locations Your labels should start with the zone abbreviation (if you use zones), the section letter (if you use sections), and then descend from 1 - 10 or A-Z from the highest point to the floor. If you have two locations side by side on a shelf, consider ending one with "L" and the other with "R" (for "left" and "right").

Rack Labeling | Creative Safety Supply Best practices of rack labeling include: Determine your picking technique. Labeling racks provides a good opportunity to take into consideration the way that products are selected. Before you apply your labels, determine which model best fits your operations: Standard, in which aisles are labeled according to numerical and alphabetical order.

Warehouse Rack Labels and Inventory Labeling Solutions - Camcode By considering your inventory system, scanner type, scanning distance and angle, and mounting method, we assure that you receive the highest value warehouse rack labeling solution. 2:32 Better Inventory Control and Data Management with Camcode's Warehouse Rack Labeling Solutions

Tips for Effective Warehouse Numbering Schemes - ID Label Inc. Warehouse Zone. Zone markers are used to identify a set of locations within a warehouse. For example, zones might be used for bulk storage, case storage, dry goods, freezer inventory, receiving, staging, etc. Aisles. One way to number warehouse aisle signs for growth is to start with aisle "10" or "BA," which allows for flexibility.

Warehouse Labelling 101 - Best Warehouse Labels And Labelling Ideas Benefits Of Proper Warehouse Labelling. Better inventory management: Warehouse labelling makes it easier for you to manage your inventory. It allows you more control over the stock, making your work much more manageable. Increased productivity: It is easier to know where everything is when the racks are labelled.

Warehouse Racking Safety Guidelines: Satisfying OSHA The iGPS plastic pallet is able to hold heavier static and dynamic loads than a reusable wood block pallet and is equipped with GS1-compliant tracking. To get started with a durable, heavy-duty plastic pallet, give our team a call at 1-800-884-0225, email a specialist at switch@igps.net, or visit our contact page. By iGPS

Warehouse Racking: The Ultimate Guide - Conger Industries Inc. Density refers to how much product or material is stored in a warehouse. Different types of warehouse racking will allow you to store more material (i.e. higher density) or less material (i.e. lower density). High-density racking systems include: Double or triple depth racks. Drive-in/drive-through. Push back.

Warehouse Locations and Bin Labeling: Best Practices and Tips - SkuVault Typically, it is the most specific a warehouse location can get. The next level of location naming is by shelf (AKA row). This is categorized as the horizontal space spanning across a rack. Racks (AKA units or section) can be thought of as large sections of shelving units that store your product.

What are the best way to label warehouse racks? - Creative Safety Supply Some of the best ways to label racks in warehouses involve: Utilizing a sequential system - This is an important aspect of using location labels for racks and other storage spaces because it will help the employee ultimately find a product. This is why alphanumeric systems work so well rather than the use of colors which don't have a clear order.

Label Magic™ - Warehouse Rack Refacing & Label Removal Dasko offers Label Magic™ as a simple solution for rack and beam cleaning, and label removal. Visit our site to learn more about Label Magic™! The Warehouse Label Specialists - (866) 286-6500. Products. Warehouse Labels; ... DASKO Label 1 New Industrial Way Suite 2 Warren, RI 02885.

How to Barcode your Warehouse - DataNinja We hope the following 8 tips help you implement a user-friendly warehouse barcoding system. 1. Make the Coding logical I mean two separate things here. (1)Make the human readable bin locations easy for humans to remember, and (2) make it easy to translate a bin location ID, to its physical location in the warehouse.

How To Label Warehouse Racks | inotec In instances of gravity-fed racking, inotec recommends placing a label at both the front and the back of the racking to serve the restocking and retrieving of products. Shelf Labels Shelf labels are a simple yet popular choice for smaller warehouses. They are commonly used for smaller volumes of racking with a basic shelf layout scheme.

Post a Comment for "42 best way to label warehouse racking"